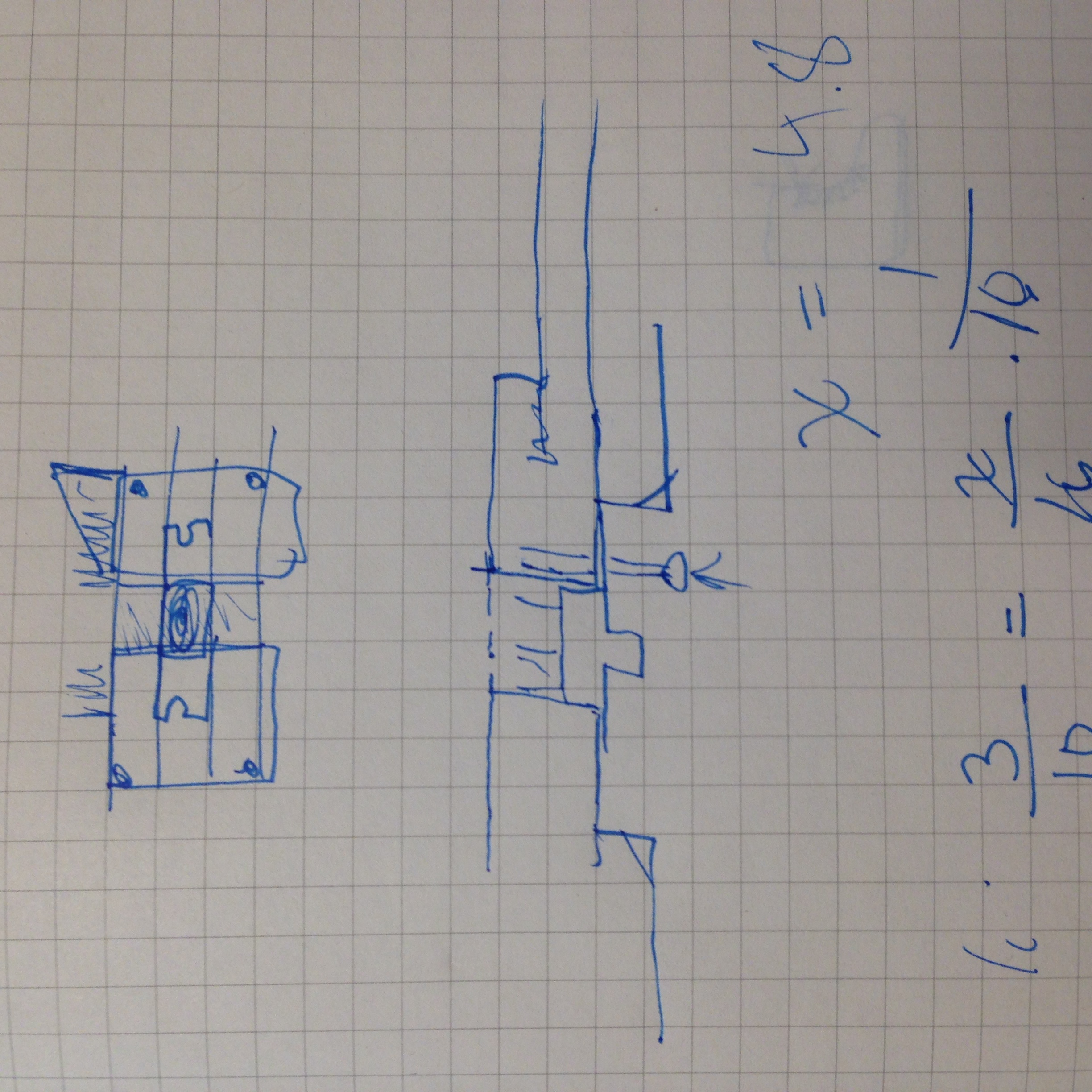

This is a prototype enclosure for the Haptec Bike Navigation System I am presenting with my team for the ITP Winter Show. The angular design fits well inside a bike frame and suggests forward motion and directionality.

Some features: an inset & interior support for a power switch. Slots for straps to affix to the bike & I'm especially pleased with the pressfit insets for ceramic disc magnets for the removable lid.

The circuit design is still in process so more openings for a battery charger and a bluetooth module are in order.

Things I would do differently or will do further: create contoured layers to constrain the interior components/circuit as well as external contours to acommodate the main bike frame bar this will enclosure hang from.

This design is an improvement on a few previous prototypes and is based on/related to the LED circuit enclosure.